Even at this stage, I am impresses by the sense of space there is in this show-box sized model.

There are several windows on the forge, each with a minimum of 6 separately glazed sections.

Working on the windows for the shop, I fabricated them externally from the model, so I could paint them before inserting into the wall apertures. This was a very neat method, but sometimes took 3 or 4 attempts to glue the assembly - due to the tiny cross section area of the glazing bars.

When it came to the forge, I decided to build the window frames up in-situ to help make the assembly somewhat easier. The secret seems to be to get the glazing bars exactly the right dimension to stay in place without adhesive. It then all holds together to allow Cyanoacrylate to be introduced on, a needle.

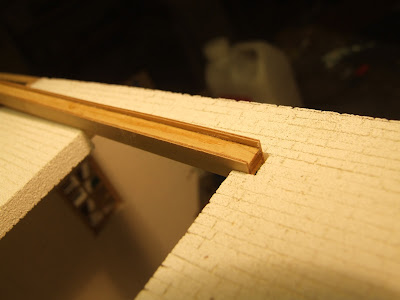

I used birch play and obeche to produce an RSJ for the forge entrance door.

When the "I" section was assembled, the beam was cut to length and spray-painted with red oxide to match the original.

Just like the on the barn model, I used 1.5mm thick obeche to produce planking for the two double doors of the forge.

The hinge fixing bolts were replicated using the tiniest pins available and filed down to amore realistic dimension and inserted into 0.5mm diameter prepared holes.

No comments:

Post a Comment